Metso The Late Model Technology Dry Granulator Process ...

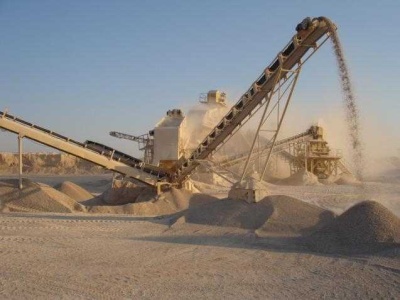

Stone Crusher Product. Jaw crusher As the first process of stone crushing line, Jaw Crusher always plays important role. Diesel engine jaw crusher is a crusher with diesel engine motor, which means it is powered by diesel engine, not electricity.