Power Plants | Continental Belting Pvt Ltd

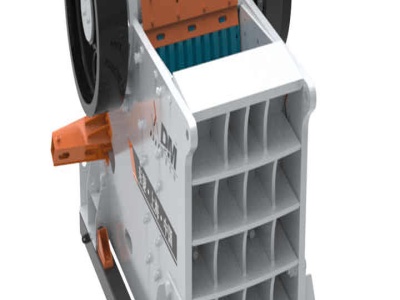

M24 Our range of M24 (24MPa) Conveyor Belts are abrasion resistant and highly resistant to cuts and gouges. These are mainly used in all mining industries and process industries such as cement (limestone), steel (crushed metallic ores), stone crushing industries (granite blue metal) Know more A bucket elevator can elevate a variety of Read More