(PDF) Review of the inpit crushing and conveying (IPCC ...

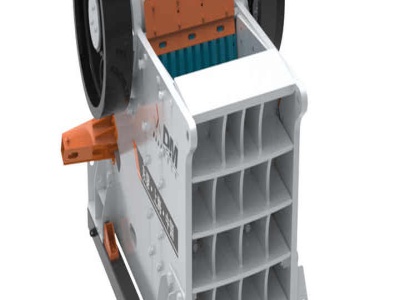

Twin Buttes pit gets bigger, 550000 tones moved out of pit each day. World Mining, PP. 7275. Island copper: inpit crusher and conveyor system under construction