DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

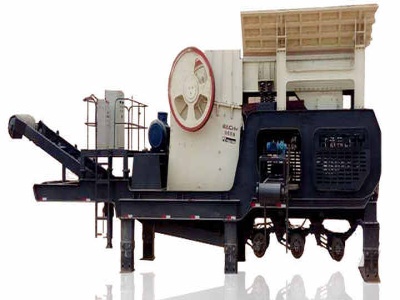

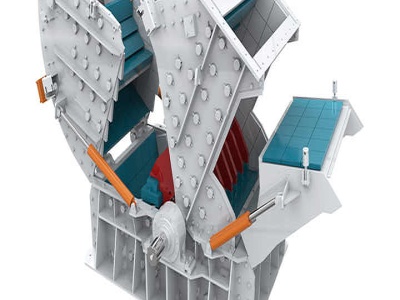

(Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material. The present mill inlet chute can be used for the two compartment ball mills only in which primary and finish grinding both are takes place. It may be a closed or open circuit grinding systems.