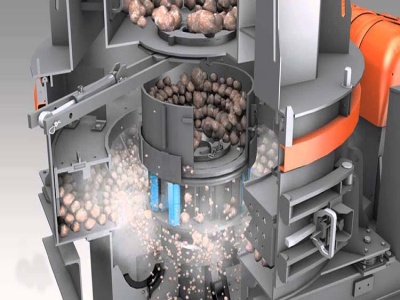

Vertical Mills

Aug 13, 2015 · Vertical Mills. A significant portion of the cost to produce a ton of cement resides in the grinding costs. The industry standard for decades has been horizontal ball mills which rely upon heavy balls cascading inside a fast turning mill to .