Plant Layout And Material Handling Of Cement Factory

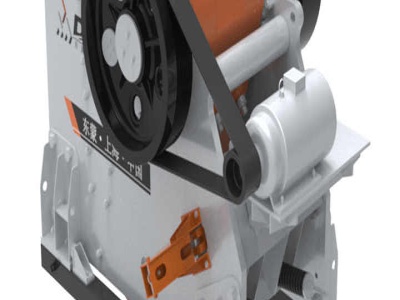

Plant Layout And Material Handling Of Cement Factory. The plant stores the materials before they are homogenized quarry 3 CRUSHING TRANSPORTATION 2 TRANSPORT The raw materials are loaded into a dumper crushing conveyor Next dumper storage at the.

![[SOLVED!] PLANT LAYOUT AND MATERIAL HANDLING on .](/um7yinb/811.jpg)

![[SOLVED!] PLANT LAYOUT AND MATERIAL HANDLING on .](/um7yinb/815.jpg)