Triple Roll Crushers | McLanahan

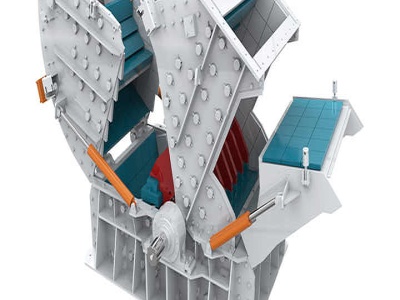

McLanahan Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in a single pass. Depending on the duty class, they can be used in most ROM appliions, such as coal, salt, lime, pet coke and potash operations. Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction .