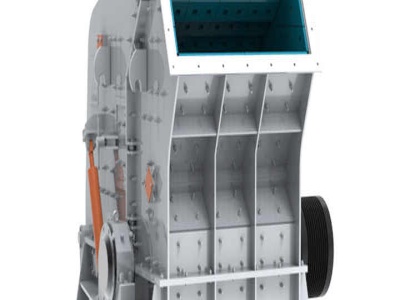

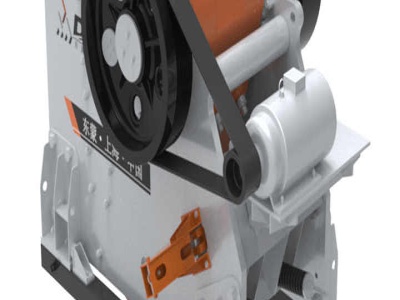

Grinding mill machine, mineral mill, raymond mill ...

Henan Liming Heavy Industry Science and Technology Co., Ltd. Was founded in 1987, which mainly manufacture large and mediumsized crushing and grinding equipment. It is a modern jointstock corporation with research, manufacturing and sales together. The Headquarter is loed in HITECH Industry Development Zone of Zhengzhou and covers 80000 m ².