Cement Grinding Unit

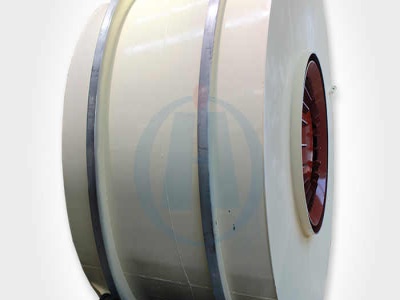

Cement grinding unit is also called the cement grinding plant. It consists of cement ball mill, dust collector, belt conveyor, bucket elevator, cement silo, powder concentrator, etc. AGICO provides highquality clinker grinders and advanced cement grinding technology.