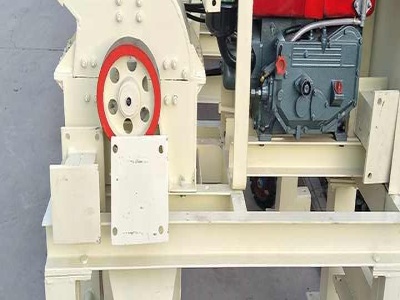

iron ore crushing and screening plant diagrams Mar

Iron Ore Crushing Plant Flow Chart Kenya. mobile crushing and screening plants sbm mi. Mobile Crushing Plant For Sale. Find Plants Screening Crushing For Sale at Trade Earthmovers, Crushing is the first stage in apatite mining operation Crusher machine is vital equipment for apatite mining SBM is the pioneer in stone crushing technology, Mobile Crushing Plants for Sale New Mobile .