YILDIRIM GROUP of COMPANIES

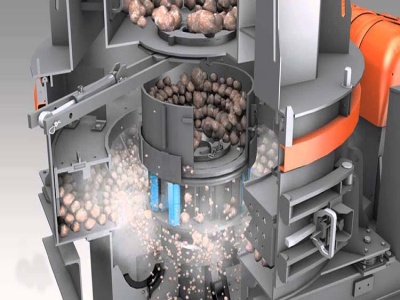

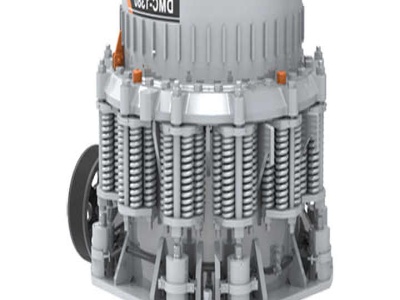

Voskhod Chrome is comprised of a stateoftheart underground mine and a modern ore processing plant. The mine's proven reserves are approximately 20 million tons with a chrome/iron ratio of ::1, one of the highest in the world. Voskhod Chrome currently has an annual chrome ore production capacity of million tons.