Jaw Crusher VS Impact Crusher | What's The Difference | MC

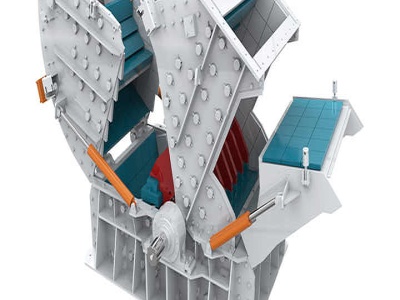

Jaw crusher is mainly composed of frame, eccentric wheel, flywheel, moving jaw, side guard plate, elbow back seat, reset spring, fixed jaw plate and movable jaw plate etc. The jaw crusher uses power to drive the jaw plate to move periodically to extrude the .