Open Pit Mining

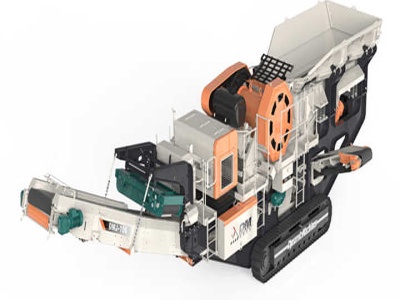

Openpit mining is the process of extracting rock or minerals from the earth through their removal from an open pit or borrow. Figure Openpit mine [16]. Surface mining is usually used to develop coal seams and deposits of many other minerals, but their feasibilities vary with the nature of the body ore.