Vishal Shukla

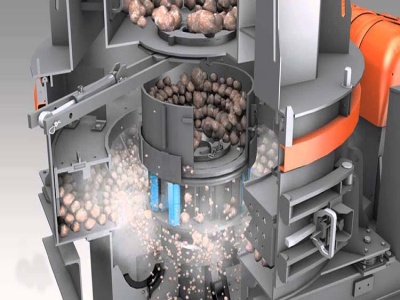

Led a team for slime beneficiation circuit modifiion to increase plant yield by integration of new technology. Expert in process audit and circuit optimization to achieve desired result. Expert in iron ore processing, Iron ore handling, Pile prepration and profile monitoring, Pellet and sinter Feed preparation, Grinding and filtration.