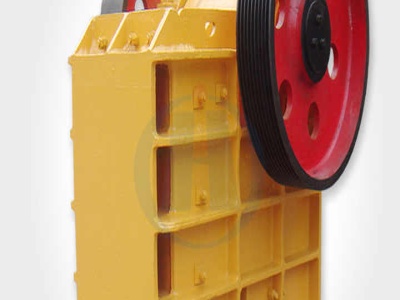

sudan sand crusher machine

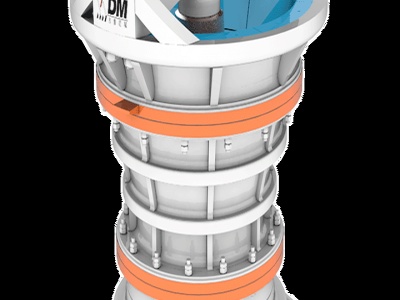

VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry mills. With a decade of research of mills, vertical grinding mill is designed and manufactured based on our advanced design idea, in combination with the european technology and the market demand. VM Vertical Roller Mill adopts ...