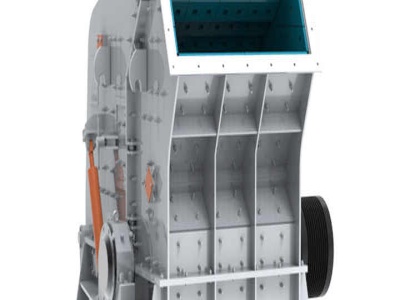

Impact Crushing vs. Cone; The Effect on Aggregate LA ...

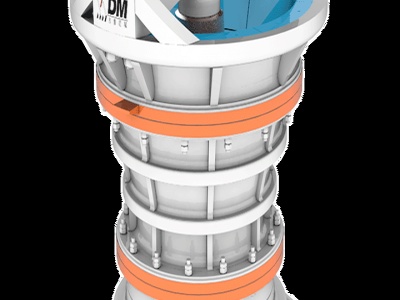

Jan 15, 2016 · In the cone crusher, the material is sheared off and the natural cracks remain in the material. Stay tuned, further posts will be coming that will examine the pros and cons of .