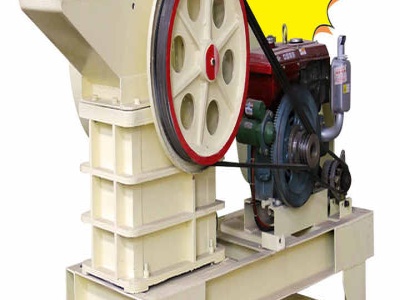

ball mill model operation maintenance procedure

Ball Mill Maintenance Procedures. Ball Mill Maintenance Procedures A wide variety of ball mill process options are available to you such as key selling points applicable industries and warranty Ball Mill Maintenance amp Installation Procedure 2020 9 12 183 Metallurgical ContentBall Mill Maintenance . Get Price