USB2

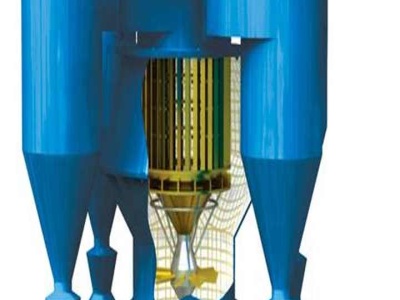

The present invention is directed toward a material handling, processing and milling facility which utilizes ball milling as a means for material grinding, mixing or mechanical alloying of materials. The system includes an automatic ball charging, agitating and indexing assembly, constructed and arranged to deagglomerate and directly distribute a plurality of grinding balls to the facility.