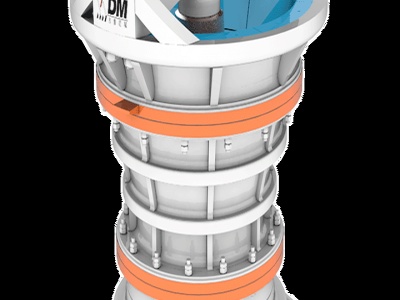

Cement Vertical Roller Grinding Mill Pdf EXODUS Mining ...

Vertical Cement Mill Authorstream. Investment return chaeng can provide a variety of schemes for cement grinding and make a choice according to the actual situation and needs of customers items scheme i closedcircuit ball mill system scheme ii combined grinding system scheme iii vertical roller mill finish grinding system cement types po425 po425 po425 cement ratio