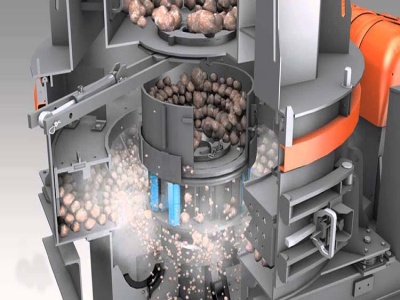

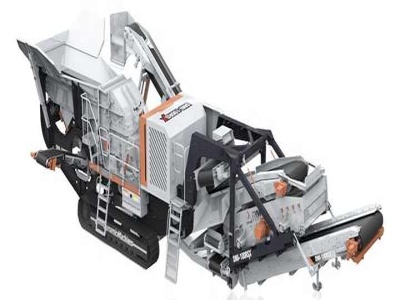

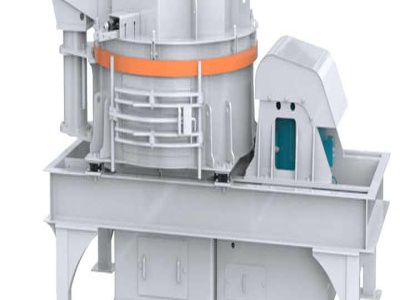

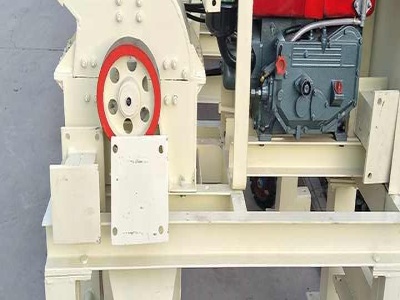

Roller Crusher

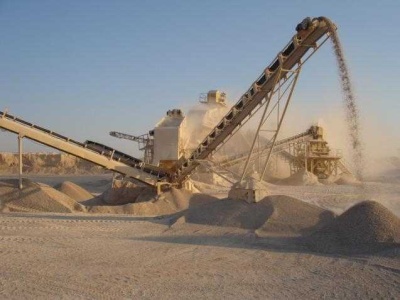

Feature. 1. Used for almost any material and for crushing up to mm. 2. More economical because of its higher production capacity and lower power requirement. 3. Segmented roll designs available in a wide selection of tooth configurations and abrasionresistant materials for rugged performance and long life. 4.