® Mobile crushing screening plants

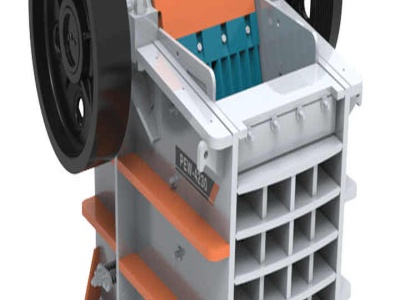

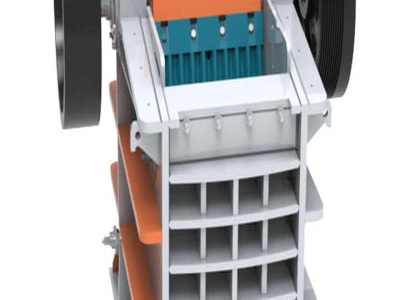

trailer. The LT96 is our most compact mobile jaw crushing plant, providing great performance especially in recycling and the contracting segment. LT96 is built around the Nordberg® C96™ jaw crusher. The sturdy, bolted and pinned design increases the durability of the crusher against shock loads. The swinging function is available