problem pulverizer | Mining Quarry Plant

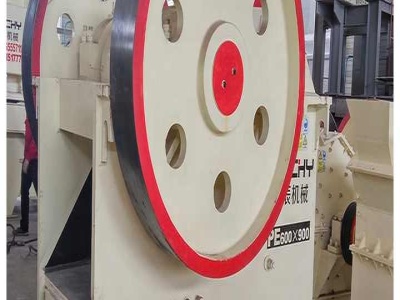

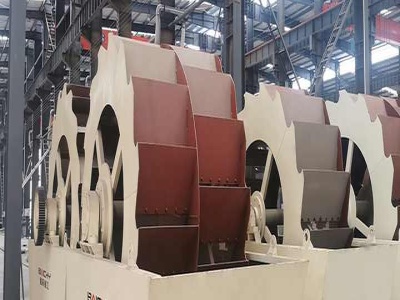

Mar 25, 2013 · If a problem is indied with one technology, .. Each mill pulverizer is responsible for about 130 megawatts of power. When the coal quality is good, .. A Food Waste Processor on Steroids!: The Pulverizer – Trash Talk. Problem Solver: The Pulverizer. The Bokashicycle Food Waste Pulverizer is a 500lb., 3 HP monster that gobbles up food ...