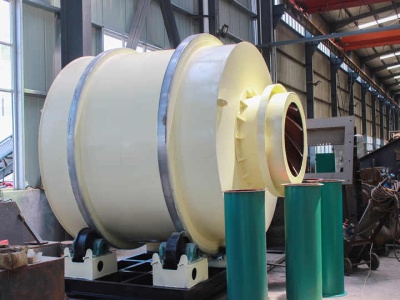

Nickel Ore Processing Sag Mill Feed Bin

Degrussa Processing Plant Overview Ausimm Bulletin, The crusher product feeds into a crushed ore bin with a live capacity of approximately 12 hrs the ore is reclaimed from the bin using three vibrating feeders the primary sag mill is 73 m x 335 m with a 34 mw variable speed motor during commissioning the s Nickel Ore Processing Sag Mill Feed Bin