Mining Technology in the Nineteenth Century | ONE

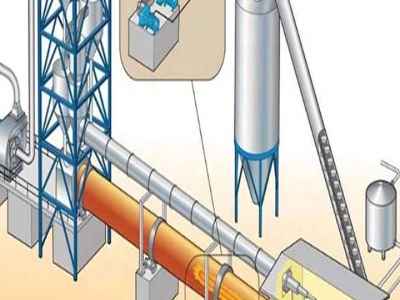

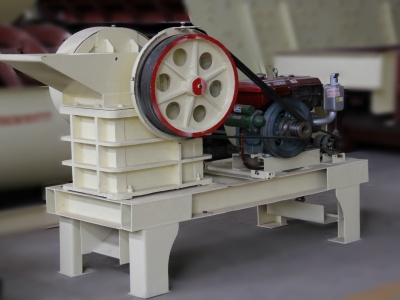

Ore processing technologies extract economically valuable minerals and metals. They include the collection of naturally occurring metals and minerals (, placer gold or lode silver), crushing and grinding ores, mechanical concentration of ores containing metals and minerals, and breaking down the ores with chemical, heat, and electrical ...