Design of a cryogenic grinding system for spices

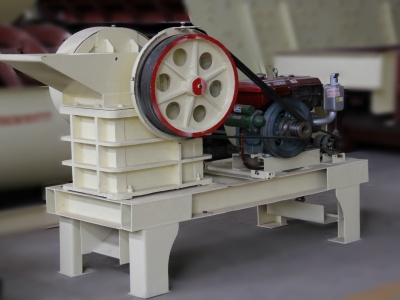

Therefore, a cryogenic grinding system was designed and developed to cool the spices before feeding to the grinder and also maintain the cryogenic temperature in the grinding zone. The main components of the cryogenic grinding system are a precooler and grinder. The precooler consists of a screw conveyor assembly, a compressor, a liquid ...