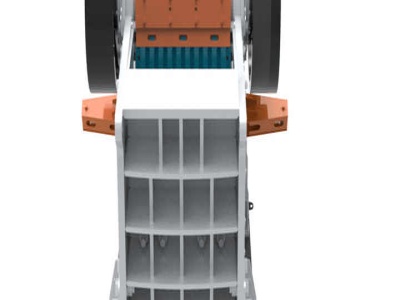

Clinker Breaker

Our clinker breaker designed with five advantages: highspeed, wearable parts materials, body structure, the design of grid, steel plate extrusion and impact crushing, completely realize the expected size with longterms stability, and features in high efficiency, low power consumption, dust proof and consumable parts are longlived, lowcost accessories, high rate of operation and easy to ...