Proposal Kompre 2 | Mill (Grinding) | Minerals

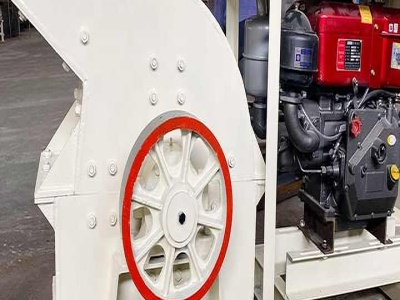

Milling may be performed by using tumbling or stirredmill, a horizontal hollow cylinder (shell), filled with grindingmedia together with ore in a certain volume and ratio Rotating the shell causes the media and ore minerals within the cylinder to collide each other. Tumbling mill with ball .