Size Reduction

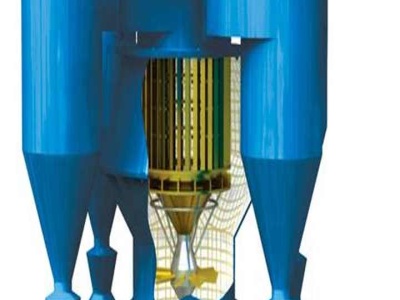

Size reduction in leaftype materials should be done in such a manner that the sample does not contain any stem or stalk. The size reduction should be performed using a shredding mill, hammer mill, pin mill, fluted rollers, or grinders. Tobacco grinding may be considered as one prototype size reduction mechanism.