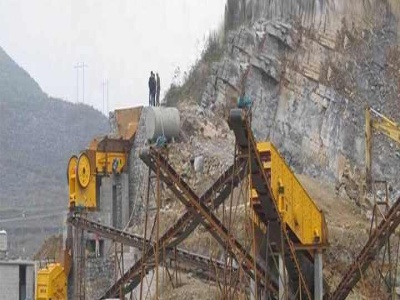

Iron Ore Production Equipment for Kazakhstan Iron Mining

Natural iron ore after crushing, grinding, magnetic separation, flotation, and other procedures can gradually elect iron. Every year we have exported a lot of iron ore processing equipment to here for local iron oreexploitation. And our equipment has been highly recognized by our users. Iron Ore Processing Line