mineral processes of gold iron

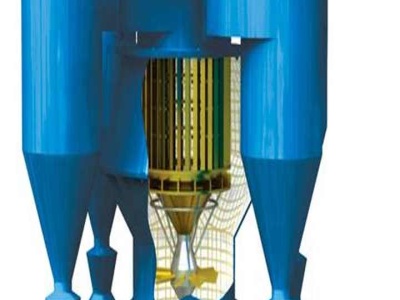

Mineral Processes Of Gold And Iron. mineral processes of gold iron Recovery Improvement of Fine Iron Ore Particles by Bentham Open Abstract Conventional gravity separation process of iron mineral » Learn More 24 Iron oxide copper gold mineral where earlier subduction related processes and.