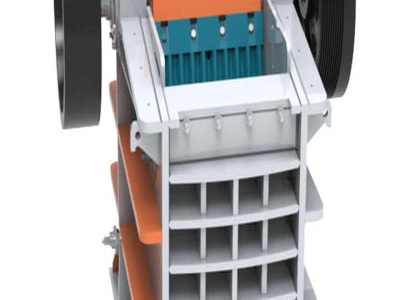

Double Disc Grinder

Doubledisc grinding with machines from Thielenhaus and ThielenhausNISSEIFlat and stamped parts are machined on the doubledisc grinding machine using a throughfeed, plungecut or oscillation process, depending on the respective scope of appliion for the "V vertical series is extremely versatile.