DADE Auctions

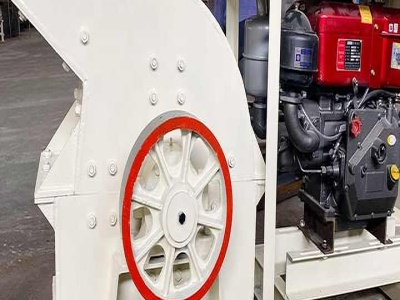

Rotor Impact Mill RPMX 1516 Completely Factory Refurbished and never placed into service. Usage areas: Metal Composites: Separation of metal composites and precrushed ferrous and nonferrous metals such as cans, window profiles, shredded electronic waste, and shredder heavy fractions Ductile metals: Cleaning and shaping of ductile metals into balls Brittlehard materials: Crushing of ...