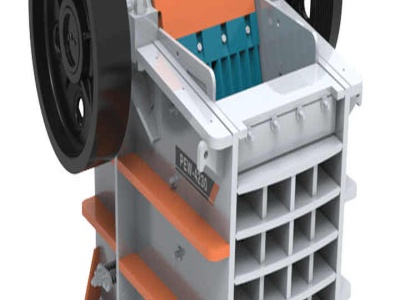

Jaw Crusher

Crusher For Sale Mobile Primary Jaw Crusher. 450 ton per hour. 1100 x 800 Crusher. There is an electrical problem and the slui pump needs repairing. It also needs a good service. BARGAIN!! Brand new going for almost R9mil.