ISO 12131:1993(en), Solid mineral fuels ? Vocabulary ...

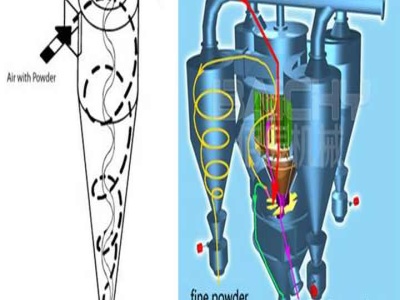

A diagram indiing, by standard symbols, the units of equipment used in the various operational steps carried out within a coal preparation plant. materials flowsheet