Simplifying the crushing process

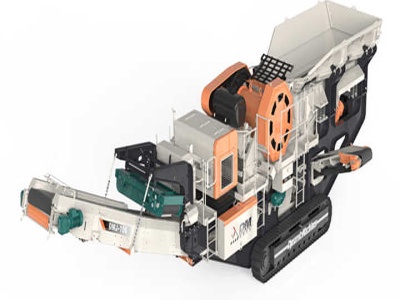

· Jaw crushers. In compression crushing, jaw crushers tend to be more of a blunt instrument compared to cone crushers. This is why jaw crushers are often used in the primary circuit stage. Jaw crushers are also known as "rock breakers" and are used to break up larger, harder materials into more manageable pieces. They tend to do well with different types of materials, and they don't ...