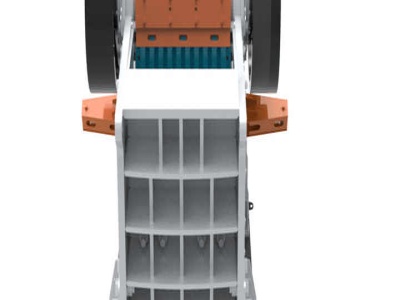

Crushers

To optimize operating costs and improve the product shape it is recommended that cone crushers are always be choke fed, meaning that the cavity should be as full of rock material as possible. This can be easily achieved by using a stockpile or a silo to regulate the inevitable fluctuation of feed material flow. Level monitoring devices detect the maximum and minimum levels of the material ...