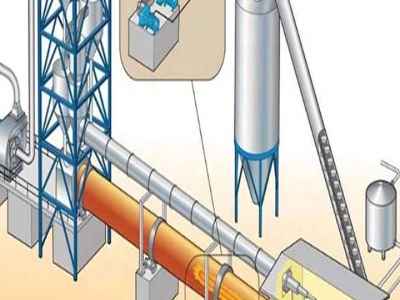

NOx Emissions from the Cement Industry

· General Information Gross NOx emissions are typically in the range of 500 to 1,500 ppm being closely related to kiln combustion conditions. In the cement industry normally, 95% of .