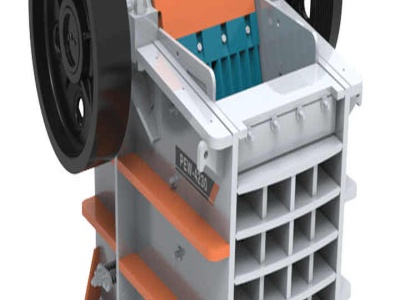

output from 50 tonne stone crushing plant | evasbm

Crushed stone ( thick ) = 65125 m3/hour. Gravel/sand ( . Compaction output at different asphalt layer . 8cm thick = 5070 tonnes/hour 12cm thick . Vary output size between 100mm and 10mm; Suitable for jobs from 50 ton to . crush concrete · crush brick · crush stone · crush kerbs ...