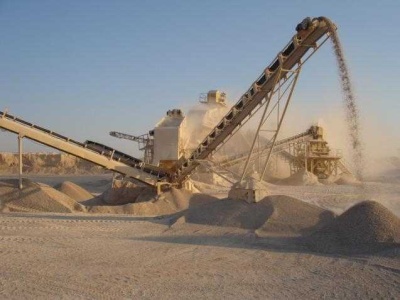

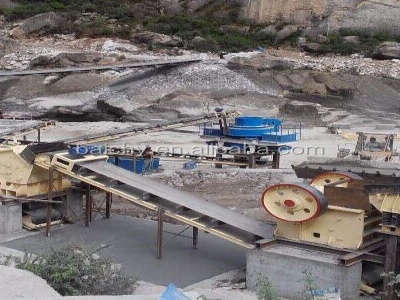

sand mould making procedure

sand mould making process, how we make castings process. sand mould making procedure. figure 30. the procedure for making a typical i read a journal that says that green sand molding is used for the process.. Read more. Sand casting Wikipedia, the free encyclopedia.