Crusher Bearings Technical White Paper | Timken

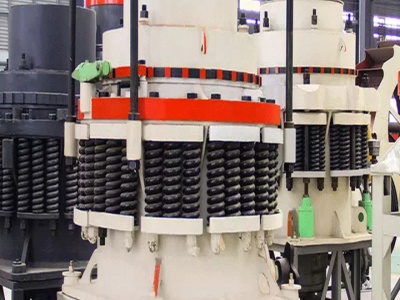

In a typical jaw crusher, two outer bearings loed on either side of the main frame support an eccentric shaft, while two inner bearings support a movable jaw. These are commonly known as "Pitman" bearings. The reciproing motion of the shaft moves the Pitman against a second, stationary jaw. As material reaches the bottom of the ...