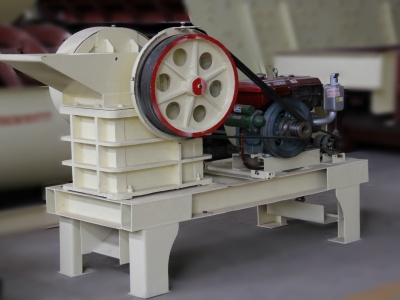

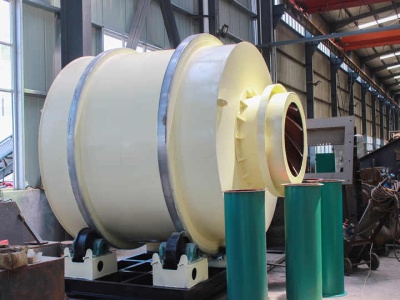

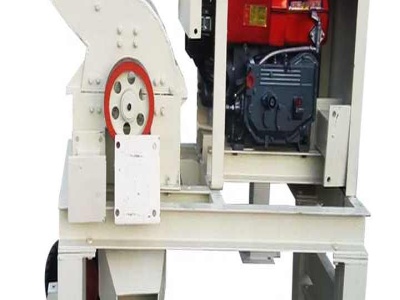

Roller Mill Components

· Roller Mill Components. Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works. In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker. These mills offer a high throughput rate and ...