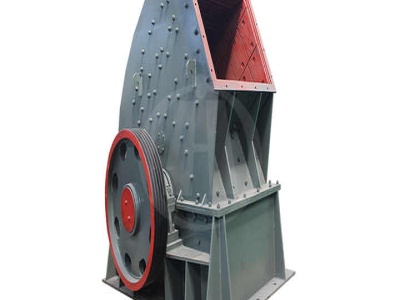

Ringmill Shredders Crushing Equipment

Fine Grinding Mill; Ringmill. American Pulverizer Ringmills utilize an exclusive rolling ring design that is the most efficient crushing element ever developed to reduce material to uniform size. Each ring freely rotates on the shaft and is held in its outward position by centrifugal force.