circuit crushing coal

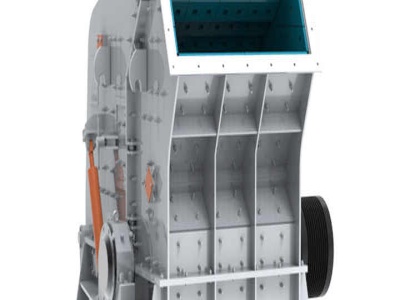

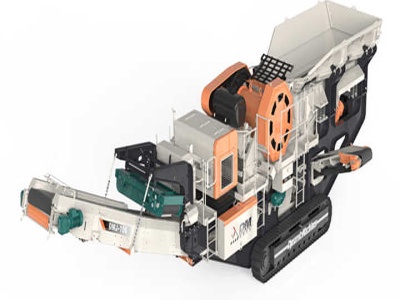

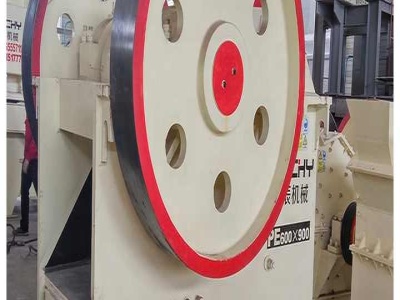

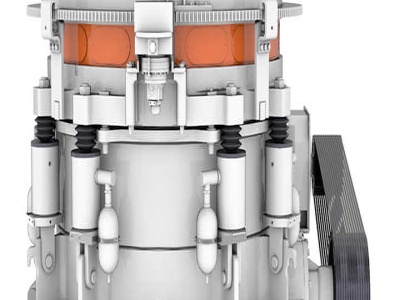

Coal crushing machine for both opencircuit coal crushing and closedcircuit coal crushing, you can always choose CGM crushing machine for coal breaking. There will . Learn more. Coal Crushing Plant, coal crusher plant, coal . Coal Crusher is acknowledged in coal processing industry for a long time. has many years manufacturing experience in ...