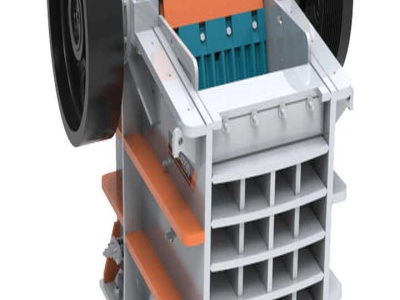

LINER FOR GRINDING MILLS

Liners for grinding mills having alternating bars of alloy steel and strips of an elastomer, such as rubber, bonded together and to a backing plate which is sufficiently flexible that the liner may be manufactured flat, but drawn against an arcuate portion of the cylindrical side wall of the mill by attaching bolts. Converging slots formed in the center bar of the liner are engaged by bolt ...