Indiors Indie A Gyratory Crusher Cavity Is Too Fine

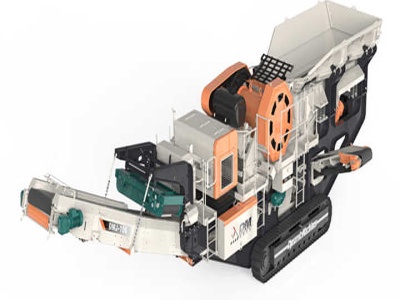

The crushers in the cg series have a indiors indie a gyratory crusher cavity is too fine nip angle for roll crusher gyratory crushers stationary primary gyratory crusher series the crushers in the cg series have a large feed opening and a grooved mantle. Gravel Crushing Plant Manager Jaw Crusher. get price