ThyssenKrupp Industrial Solutions

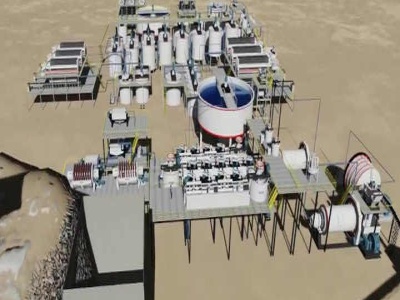

Storage silo and bin For the pure storage of finegrained or powdery products such as filter dusts, raw meal, cement or coal dust and other additives a broad range of different silos and bins are used, which are suited to the respective material properties.