torque in rolling mills calculation formula with example

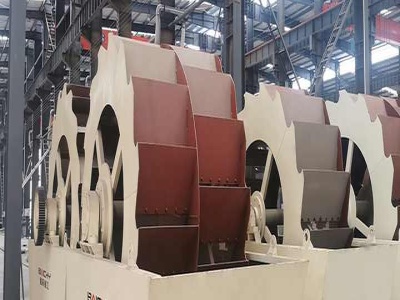

Mill load roll force, torque, power during steel rolling MILL LOAD Roll Force, Torque, Power The Mill Load appliion is specifically developed for mill design/operation engineers to calculate roll separating force, rolling torque and power, etc Typically, load calculation is needed for an existing mill when a new rolling process is applied either with higher reduction or in lower temperature ...