A discussion

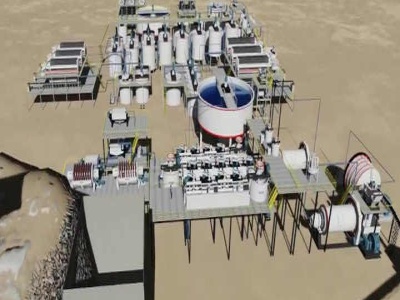

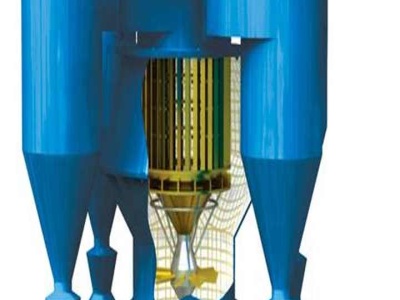

The idea of HDTT is to stack the pulp to form a self supporting conical pile thus reducing the height and retention forces of the containing perimeter embankments. Increasing the thickness of the tailings pulp ( increasing the %solid concentration) creates higher beach slopes angles in comparison to tailings discharged with a higher content of water ( lower %solid .