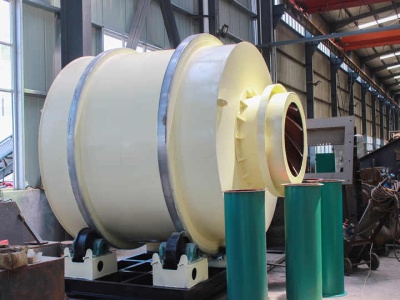

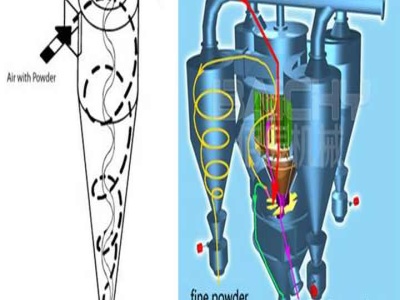

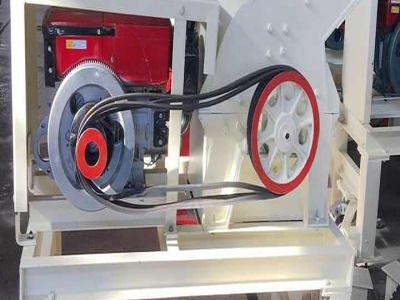

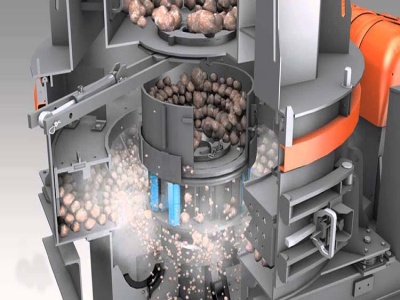

processing of minerals crushing

Mineral Mining and Processing Effluent Guidelines . Wastewater is generated during mineral processing e g stone cutting wash water scrubber water from equipment cooling from mine dewatering and from stormwater runoff at mines and processing plants Note Hard rock mining of metals ores is covered in the Ore Mining Effluent Guidelines 40 CFR Part 440 Facilities Covered