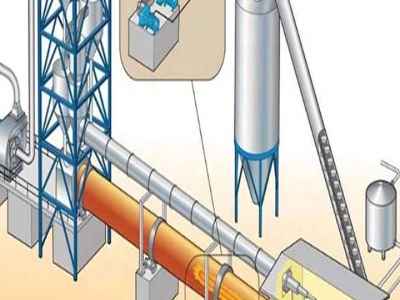

Pulping Process

Steam is produced in the chemical pulping process, when the hot pulp and cooking liquor are reduced to atmospheric pressure at the end of the cooking cycle. In batch digesters, steam is typically stored as hot water in an accumulator tank and in continuous digesters, extracted black liquor flows to a tank where it is flashed. Recovered heat generated from these processes can be used in other ...